To keep your traction motor running smoothly, regularly inspect and maintain the bearings for signs of wear, contamination, or noise, and replace them as needed. Make certain the cooling system stays clean and unobstructed, checking coolant levels and fan functionality to prevent overheating. Proper lubrication is key; use the right lubricants and adhere to recommended schedules to reduce friction and wear. Continuing with these practices will help you maximize motor lifespan and performance.

Key Takeaways

- Regularly inspect bearings for noise, vibration, and lubrication condition to prevent premature wear and failure.

- Ensure cooling systems are clean, unobstructed, and functioning properly to prevent overheating and insulation damage.

- Use manufacturer-recommended lubricants and adhere to proper lubrication intervals for optimal bearing performance.

- Check insulation resistance periodically to detect moisture or contamination that could compromise motor safety.

- Maintain comprehensive maintenance routines to monitor all components, reducing downtime and extending motor lifespan.

Maintaining your traction motors is essential to guarantee reliable and efficient operation of your vehicle or equipment. Whether you’re working with traditional brushed motors or advanced brushless motors, consistent maintenance ensures longevity and peak performance. One of the key aspects of this upkeep involves inspecting the insulation of your motors. Proper insulation checks help prevent electrical faults, short circuits, and potential motor failures. Regularly testing the insulation resistance can identify deterioration early, especially in harsh environments where moisture, dust, or chemicals may compromise the motor’s integrity. For brushless motors, which rely heavily on precise electronic control, ensuring the insulation remains intact is critical for avoiding unexpected downtime or damage to sensitive components. Additionally, maintaining proper filter replacement and ensuring clean airflow can prevent dust accumulation that may affect motor cooling and performance.

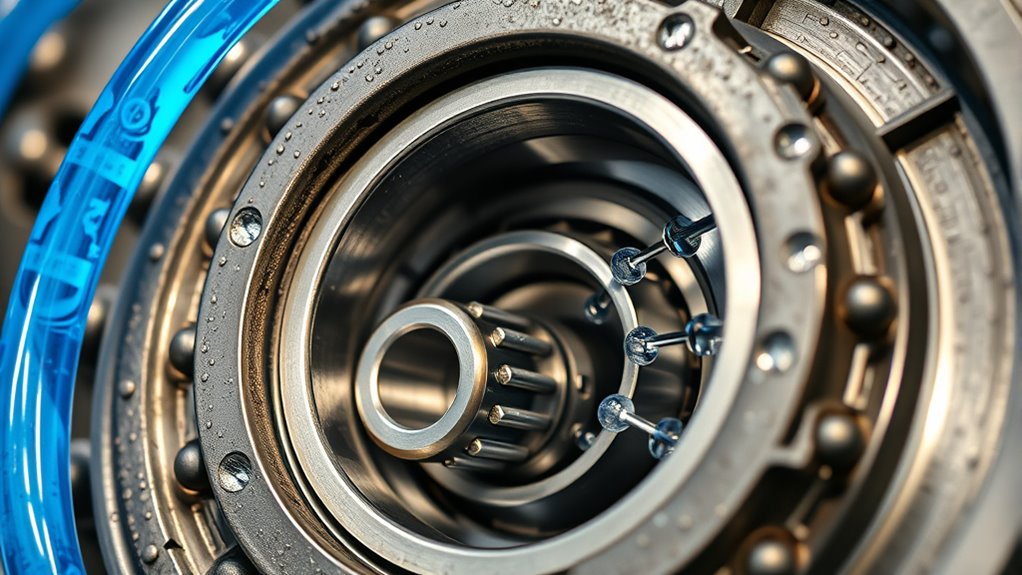

Beyond insulation, attention to the bearings is fundamental. Bearings support the rotor and allow smooth rotation, but they are susceptible to wear, contamination, and lubrication issues. If bearings become worn or dirty, friction increases, generating heat that can damage the motor’s internal parts. You should routinely check for unusual noises, vibrations, or excessive heat during operation. These signs often indicate bearing problems that need immediate attention. When inspecting, look for signs of corrosion or dirt buildup, and replace bearings if necessary. Proper alignment is also essential, as misaligned bearings can accelerate wear and lead to uneven load distribution, ultimately shortening the motor’s lifespan.

Cooling is another critical factor in maintaining your traction motors. Overheating can cause insulation breakdown, reduce efficiency, and lead to catastrophic failures. Ensure your cooling systems—whether air-cooled or liquid-cooled—are functioning correctly. Clear any obstructions from vents or cooling fins and verify the coolant levels if applicable. Regularly inspect fans, pumps, and heat exchangers to confirm they operate efficiently. A well-maintained cooling system not only prevents thermal damage but also keeps the motor running at peak temperatures, improving overall performance and extending its service life.

Lubrication plays a key role in reducing friction and wear within your motors. Use the manufacturer-recommended lubricants and follow the specified intervals for lubrication. Over-lubrication can attract dirt and cause additional issues, while under-lubrication leads to increased friction and potential bearing failure. Always check lubrication points for signs of contamination or degradation. When handling lubricants, ensure you clean the surrounding areas to prevent dirt from entering the system. Proper lubrication, combined with regular inspections, ensures your motors operate smoothly, with minimal downtime and maintenance costs.

Frequently Asked Questions

How Often Should Traction Motor Bearings Be Replaced?

You should replace traction motor bearings during regular bearing inspections, typically every 20,000 to 30,000 miles or as recommended by the manufacturer. Keep an eye out for signs like unusual noise, vibration, or overheating, which indicate it’s time for replacement. Following proper replacement intervals helps prevent unexpected failures, ensuring smooth operation and prolonging the life of your traction motor. Regular checks are essential for peak performance.

What Are the Signs of Cooling System Failure?

A cooling system failure can be as dramatic as a thunderstorm for your traction motor. Watch for signs like coolant leaks or unusual puddles indicating leaks, which compromise cooling efficiency. Thermal sensors will alert you with high temperature readings, signaling overheating. If you notice these signs, act fast. Ignoring them could lead to severe damage or complete motor failure, turning your smooth ride into a costly disaster.

How Does Lubrication Type Affect Motor Performance?

You need to choose the right lubrication type to guarantee ideal motor performance. Proper lubrication compatibility prevents damage, while incorrect types can cause lubrication contamination, leading to increased wear and efficiency loss. By selecting compatible lubricants, you minimize friction and overheating, extending bearing life. Keep in mind that using the wrong lubricant can result in contamination, which hampers motor performance and causes costly repairs over time.

Can Improper Maintenance Cause Motor Overheating?

Think of your motor as a finely tuned engine—improper maintenance can cause heat buildup, leading to insulation breakdown. When you neglect proper lubrication or cooling, the motor’s components struggle to dissipate heat, risking overheating. This not only damages insulation but also shortens the motor’s lifespan. Regular inspections and timely maintenance are vital to prevent overheating and guarantee your traction motor runs smoothly and efficiently.

What Safety Precautions Are Necessary During Maintenance?

During maintenance, you need to follow safety precautions like wearing personal protective equipment, including gloves and eye protection, to prevent injuries. Always implement lockout/tagout procedures to make sure the motor is disconnected from power sources, preventing accidental startup. Be cautious of hot surfaces and moving parts, and work in a well-ventilated area. By following these steps, you keep yourself safe while maintaining traction motors effectively.

Conclusion

Keep your traction motor in top shape, and you’ll release the power of a locomotive, a rocket, a tornado—all in one! Proper bearings, cooling, and lubrication aren’t just maintenance—they’re the secret ingredients to unstoppable performance. Neglect them, and you risk disaster faster than you can say “breakdown.” So stay vigilant, stay relentless, and watch your motor roar like a beast unleashed—because with the right care, you’re unstoppable!