Supply chain disruptions directly slow down electric bus production by causing shortages of critical parts like batteries and electrical systems. These delays push back manufacturing schedules, increase costs, and make it harder to meet rising demand. Dependence on limited suppliers and global materials adds vulnerability, risking further setbacks. As costs rise and timelines stretch, your plans for deployment may be impacted. Understanding these challenges helps you grasp the full scope—keep exploring to learn more.

Key Takeaways

- Supply chain disruptions delay electric bus manufacturing, causing missed deadlines and increased production costs.

- Dependence on limited global suppliers makes the industry vulnerable to shortages and geopolitical issues.

- Component shortages, especially batteries, hinder integration of advanced technologies and slow deployment.

- Infrastructure delays and high costs restrict charging station development, impacting overall electric bus deployment.

- Rising costs and delays reduce market competitiveness, risking financial strain and industry consolidation.

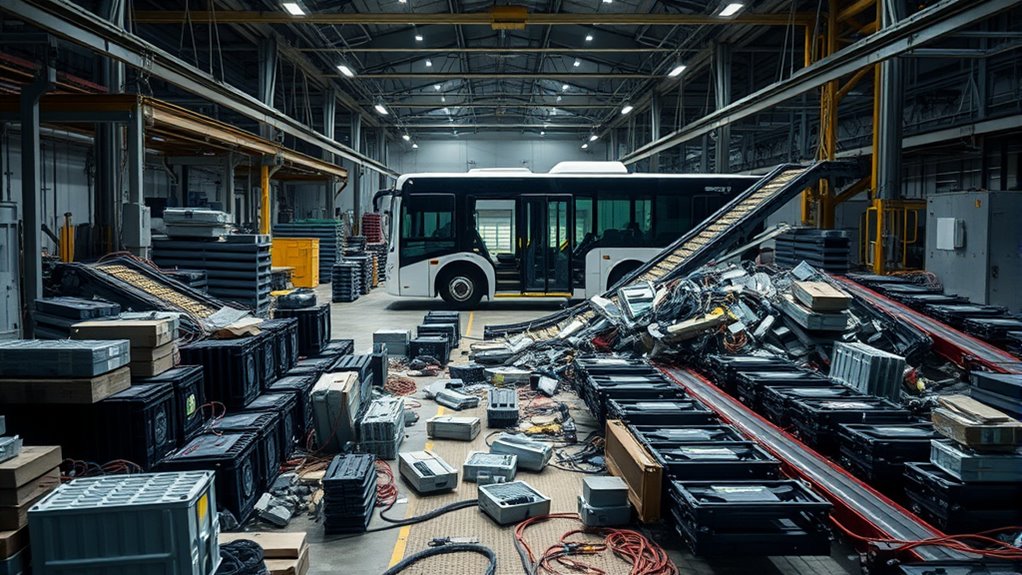

Supply chain disruptions are substantially impacting electric bus production, presenting a major hurdle for manufacturers aiming to meet rising demand. These disruptions make it difficult for you to source critical components like batteries and electrical systems, which are essential for building electric buses. When component availability drops or delays occur, your production schedules stall, causing missed deadlines and increased costs.

Supply chain disruptions hinder electric bus production, causing delays, increased costs, and missed deadlines.

This situation is further complicated by your reliance on raw materials sourced from around the globe. If a key supplier faces issues or geopolitical tensions flare, your entire supply chain becomes vulnerable, threatening to halt or slow down manufacturing altogether. Vetted suppliers are crucial in maintaining stability in your supply chain, helping you navigate these unpredictable conditions.

The lingering effects of the pandemic continue to ripple through your supply chain, making your operations less predictable. Suppliers may experience financial instability, leading to shortages or delays that ripple through your production line. You might find yourself scrambling to secure enough components, often facing higher prices due to scarcity.

These increased costs cut into your margins and can make your electric buses less competitive in the market. Small-scale orders from transit districts, while beneficial in terms of market reach, add another layer of complexity. Managing these varied orders under constrained supply conditions strains your resources and complicates production planning.

Technological challenges also stem from supply chain disruptions. You may struggle with integrating new, more efficient battery technologies that could reduce dependency on scarce raw materials. Building the infrastructure for charging electric buses is another costly hurdle; limited routes and charging stations can restrict deployment and increase infrastructure expenses.

Managing charging systems adds a layer of complexity, requiring careful planning to balance charging times and locations, especially when components or infrastructure are delayed. Improvements in battery technology, which could help stabilize supply chains by reducing reliance on critical materials, are often delayed due to these disruptions, further prolonging your efforts to modernize and scale production.

Market dynamics intensify the pressure. Despite supply chain issues, demand for electric buses continues to grow, driven by regulatory policies and government incentives. You face stiff competition from traditional diesel and CNG bus manufacturers, making timely delivery vital.

Overreliance on a small number of suppliers increases your risk—if one supplier falters, your entire production line is at risk. To stay competitive, you need resilient supply chains that can adapt quickly to disruptions, but achieving this is no small feat.

Financially, ongoing supply chain issues threaten your stability. Increased costs and delayed deliveries can lead to financial strain, forcing some companies to consider mergers or even market exits. Strategic decisions become essential as you weigh whether to continue operations or pivot to new sourcing strategies.

Additionally, exploring alternative supply sources and diversifying your supplier base can help mitigate risks and improve overall resilience supply chain resilience. In this environment, your ability to navigate supply chain disruptions directly influences your capacity to meet demand, maintain profitability, and push forward with electric bus innovation.

Frequently Asked Questions

How Do Supply Chain Issues Affect Electric Bus Pricing?

Supply chain issues directly impact electric bus pricing by increasing costs for essential parts and materials. You’ll see higher prices due to rising raw material costs, tariffs, and delays in component delivery.

These added expenses force manufacturers to raise their prices, which can make electric buses less affordable for you.

To combat this, companies are shifting to local sourcing and investing in technology to reduce reliance on volatile supply chains.

What Alternative Materials Are Manufacturers Considering Due to Shortages?

You’re looking into alternative materials manufacturers consider due to shortages. They’re exploring options like LFP batteries to reduce reliance on nickel and cobalt.

They’re even shifting to sodium-ion batteries to bypass lithium issues. Aluminum and composites replace steel and traditional components.

Recycled and second-life batteries help ease demand. Local sourcing, nearshoring, and vertical integration also play roles in securing materials and maintaining production amid supply chain challenges.

How Long Do Supply Chain Disruptions Typically Last?

You should know that supply chain disruptions typically last around three months, with some taking up to five months. Remarkably, these disruptions happen at least once every four years for most companies.

Shipping delays can stretch to 10-14 days, and delays of up to 20 days are common now. During this time, businesses need to stay resilient and act quickly to minimize costs and keep production on track.

What Regions Are Most Impacted by Supply Chain Delays?

You should know that supply chain delays hit regions differently, with Asia being especially affected due to its role in component sourcing.

North America also faces significant challenges, particularly in the U.S. and Canada, where infrastructure and regulatory differences complicate things.

Europe experiences disruptions as well, though policies support electrification.

Emerging markets like South America and Africa are less advanced but still feel the impacts of global supply issues.

Are There Government Policies Aiding Electric Bus Supply Recovery?

Think of government policies as the steering wheel guiding electric bus supply back on course. You’ll find initiatives like financial incentives, infrastructure grants, and collaborative strategies acting as fuel to accelerate recovery.

These policies help stabilize the supply chain, making it easier for manufacturers to meet demand. By investing in technology and infrastructure, governments are actively nurturing a resilient ecosystem, ensuring electric buses roll out smoothly and sustainably.

Conclusion

You see, supply chain disruptions have caused a 30% drop in electric bus production, highlighting how fragile the industry really is. Despite the challenges, manufacturers are adapting quickly, but the impact remains significant. Staying resilient means addressing these vulnerabilities now, or risk further delays. If you want a cleaner future, understanding these disruptions helps you appreciate the importance of a robust supply chain. Ultimately, overcoming these hurdles is essential for sustainable transportation growth.