Choosing between air and liquid cooling for bus batteries depends on your needs. Air cooling is simpler and cheaper, making it suitable for moderate use, but it may struggle in hot climates or heavy-duty applications. Liquid cooling offers superior temperature control, better safety, and consistent performance, especially under demanding conditions. Understanding their benefits and limitations helps you make the right choice for efficiency and longevity. Continuously exploring these options will reveal how to optimize your thermal management system.

Key Takeaways

- Air cooling is simpler and more cost-effective but less effective in maintaining consistent temperatures under heavy use.

- Liquid cooling offers superior temperature regulation, especially in demanding conditions, by circulating coolant directly through battery channels.

- Air cooling relies on fans and heat sinks, while liquid systems use pumps and coolant channels for efficient heat transfer.

- Liquid cooling provides better safety against overheating and thermal runaway compared to air cooling.

- The choice depends on factors like climate, performance needs, cost, system complexity, and maintenance considerations.

Have you ever wondered how electric vehicles keep their batteries safe and efficient? It all comes down to a well-designed thermal management system, which guarantees the battery operates within ideal temperature ranges. One of the key aspects of this system is battery insulation, which helps maintain stable temperatures by reducing heat exchange with the environment. Proper insulation prevents external heat from affecting the battery and reduces heat loss during cold weather, ensuring consistent performance. When insulation is effective, it also minimizes temperature fluctuations, which can degrade battery health over time.

Effective insulation stabilizes battery temperature and extends lifespan.

Cooling efficiency plays a vital role in maintaining battery safety and longevity. If a battery gets too hot during operation, it can lead to accelerated wear, reduced capacity, or even safety hazards like thermal runaway. Conversely, if it’s too cold, chemical reactions slow down, impairing power output. That’s why efficient cooling systems are essential, especially in larger vehicles like buses that have high energy demands. They help keep the battery within a narrow temperature window, enhancing performance and extending lifespan.

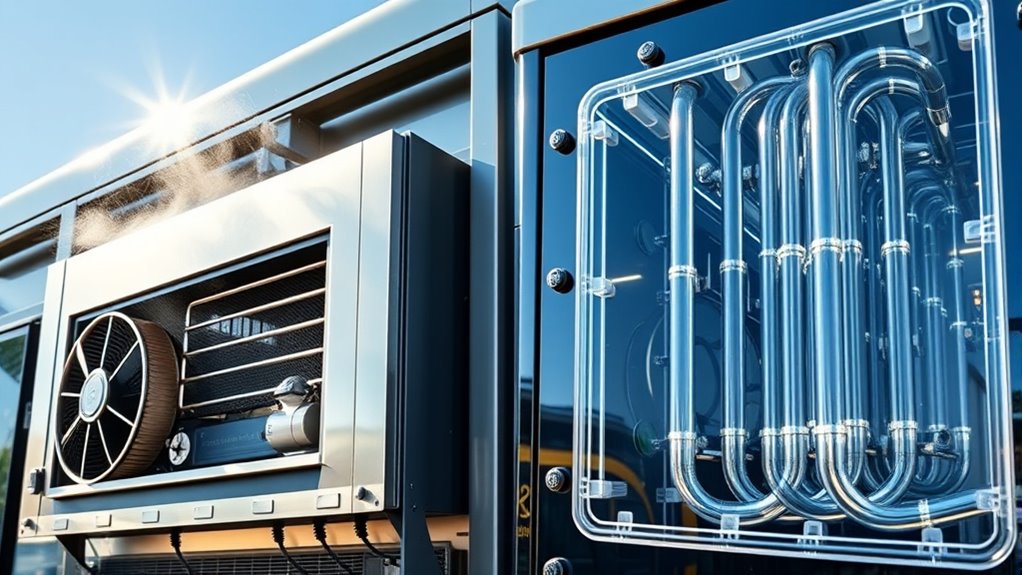

In air-cooled systems, fans blow air across the battery pack to dissipate heat. This approach is simpler and often more cost-effective, making it suitable for many applications. However, air cooling can be less effective in hot climates or during heavy use, where the cooling efficiency drops, and temperatures can rise quickly. To compensate, designers often incorporate additional insulation or heat sinks to improve temperature control, but these measures have their limits.

Liquid cooling systems, on the other hand, circulate coolant—usually water or glycol-based fluids—through channels embedded in or attached to the battery pack. This method offers superior cooling efficiency because liquids can absorb and transfer heat more effectively than air. As a result, liquid-cooled batteries maintain a more consistent temperature, even under demanding conditions. This consistency not only enhances safety by preventing overheating but also preserves battery capacity over time. The increased cooling efficiency of liquid systems allows for tighter temperature regulation, which is especially important for large bus batteries operating continuously in diverse environments.

Choosing between air and liquid cooling depends on factors like cost, complexity, and climate. Air cooling is simpler but less precise, while liquid cooling requires more maintenance and upfront investment but delivers better temperature regulation. Ultimately, the goal is to balance insulation, cooling efficiency, and system complexity to keep your bus’s battery safe, reliable, and efficient for the long haul. Additionally, advancements in battery technology are continuously improving thermal management solutions, making systems more effective and easier to maintain.

Electric Vehicle & Hybrid Diagnostics: EV Battery Systems, BMS, Thermal Management, Power Electronics, and Software Troubleshooting for Modern Cars (AutoTech series)

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does Ambient Temperature Affect Cooling System Efficiency?

Ambient temperature directly impacts your cooling system’s efficiency. When it’s hot outside, your cooling system has to work harder to dissipate heat, reducing its effectiveness. Conversely, cooler ambient temperatures improve cooling efficiency because heat transfer is easier. You might notice that in high ambient temperatures, your system struggles to keep the battery within ideal ranges, which can affect overall performance and longevity of the battery system.

What Are the Long-Term Maintenance Costs of Air Vs Liquid Cooling?

Think of maintenance costs like planting a garden—some require more watering and care over time. Liquid cooling systems generally have higher initial costs but tend to be more durable, reducing long-term expenses. Air cooling systems, while cheaper upfront, may need more frequent repairs due to wear and tear. Your choice depends on balancing upfront costs with durability factors, ultimately influencing the overall cost comparison over the system’s lifespan.

How Do Cooling Systems Impact Overall Bus Weight and Performance?

Cooling system weight directly impacts your bus’s overall weight, with liquid cooling systems typically adding more due to their pumps and coolant reservoirs. This increased weight can reduce payload capacity and slightly affect performance. Air cooling systems are lighter, which helps maintain better performance and efficiency. Consider how the cooling system’s weight and performance implications influence your bus design and operational costs before making a choice.

Are There Safety Concerns With Liquid Cooling Leaks?

Think of liquid cooling leaks like a hidden serpent; they can pose safety risks. You should prioritize leak prevention and guarantee chemical safety to avoid spills that could cause fires or damage. Regular inspections and high-quality seals reduce the danger, giving you peace of mind. Staying vigilant ensures your bus remains safe, just like a fortress guarding its precious cargo against unseen threats.

Can Hybrid Cooling Systems Combine Air and Liquid Benefits?

Yes, hybrid cooling systems can combine air and liquid benefits through hybrid integration, creating cooling synergy. You can maximize thermal management by using air cooling for general temperature regulation and liquid cooling for high-heat zones, improving efficiency and safety. This approach allows you to balance cost, complexity, and performance, ensuring your bus’s battery system stays within ideal temperature ranges while minimizing risks associated with leaks or overheating.

liquid cooling system for electric bus batteries

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Ultimately, choosing between air and liquid cooling depends on your bus’s basic needs and budget. Air offers an affordable, accessible approach, while liquid delivers longer-lasting, more reliable regulation. By balancing benefits and barriers, you’ll better beat battery burnout and boost bus brilliance. Remember, smart, strategic systems markedly simplify thermal struggles, securing safer, more sustainable, and superior transportation solutions for your fleet’s future.

Portable Bladeless Neck Fan, Birthday Gifts for Girl Boy Mom Dad, Father‘s & Mother’s Day Gifts, Wearable Cooling Fan, 5000mAh Rechargeable Battery, Essential for Camping Beach Vacation(2026 Upgraded)

Perfect Mother's Day Gift: Designed for women's comfort, this bladeless neck fan provides instant cooling to relieve menopausal…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

AIRSBOGE 40"x7" Universal Car Battery Insulation Kit – Thermal Wrap & Heat Shield Blanket for Extreme Temperature Protection, DIY Cold Weather Protector for Vehicle, Truck, 4WD, RV Batteries (1PC)

Protect Your car battery with our thickening upgrade car battery blanket: Ensure your car battery stays warm and…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.