In the long term, battery electric buses are likely to be more practical for urban routes thanks to lower upfront costs, simpler infrastructure, and ongoing technological improvements. However, hydrogen fuel cell buses may still appeal for long-distance and heavy-duty applications due to their faster refueling and longer range. Your choice depends on your operational needs and existing infrastructure, but exploring these options further can help you understand which technology best fits your future fleet plans.

Key Takeaways

- Battery electric buses offer lower initial costs and easier infrastructure deployment, making them more practical for urban fleets in the near term.

- Hydrogen fuel cell buses provide faster refueling and longer range, advantageous for long-distance and heavy-duty routes.

- Infrastructure development costs and regional availability significantly influence long-term adoption prospects for both technologies.

- Technological advances and economies of scale are expected to reduce costs and improve efficiency for both battery and hydrogen buses.

- The choice depends on regional infrastructure, operational needs, and long-term investment considerations, with each technology having distinct advantages.

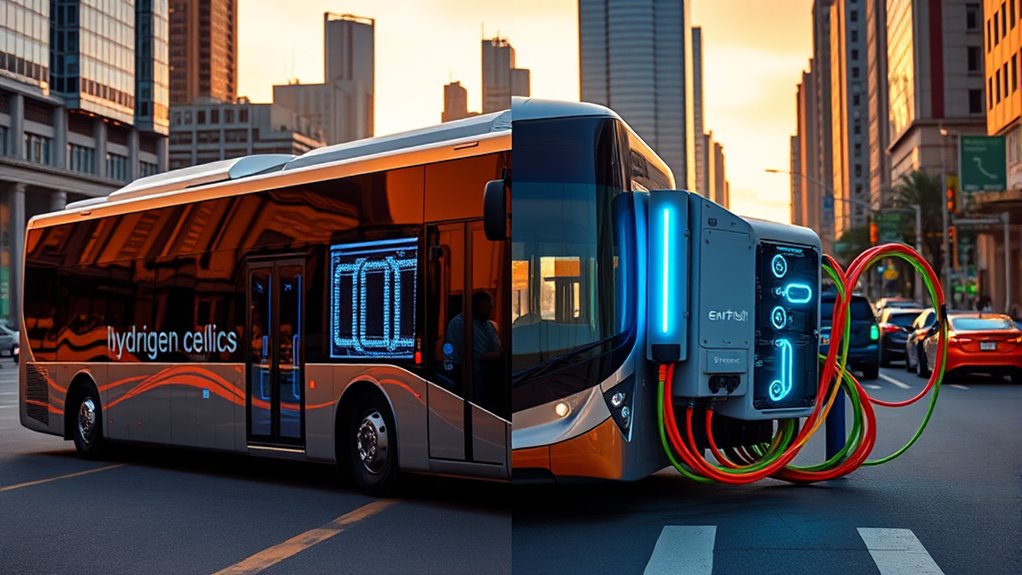

Have you ever wondered which clean energy technology is better for the future—hydrogen fuel cells or battery electric vehicles? When it comes to deploying bus fleets, this question becomes even more vital because both options present unique advantages and hurdles. One major factor to consider is infrastructure challenges. Battery electric buses require extensive charging stations, which need significant upfront investment and planning. Setting up a network of fast chargers across urban and suburban routes can be complex, especially in areas where space is limited or existing electrical grids are insufficient. You might find that scaling up battery charging infrastructure demands time and capital, potentially slowing fleet deployment. Conversely, hydrogen fuel cell buses depend on a different type of infrastructure—hydrogen refueling stations. These stations are far fewer and more expensive to build because they involve high-pressure storage, specialized safety measures, and production facilities. Developing a widespread hydrogen refueling network involves overcoming regulatory hurdles, safety concerns, and high capital costs, making the rollout more challenging in the near term. Additionally, the availability of distribution networks for hydrogen can influence the practicality of fuel cell buses in different regions.

Cost comparison is another vital aspect. Initially, battery electric buses tend to be more affordable than hydrogen fuel cell counterparts. They benefit from mature technology, established supply chains, and lower manufacturing costs. While the batteries themselves are expensive, ongoing advancements and economies of scale are gradually reducing costs. Maintenance costs for electric buses are typically lower too because they have fewer moving parts. Hydrogen buses, on the other hand, usually come with higher purchase prices due to the complexity of fuel cell technology and the cost of producing and storing hydrogen. However, some argue that hydrogen fuel cells might offer longer-term savings because they can potentially provide faster refueling times and greater range, which could reduce operational costs over time. Still, the high capital investment in infrastructure and vehicle costs makes hydrogen less immediately economical.

In the end, your decision depends on balancing these factors. Battery electric buses may be more practical for urban routes with accessible charging infrastructure and tighter budgets, thanks to their lower initial costs and easier deployment. Hydrogen fuel cells could shine in regions where long-range trips, fast refueling, and heavy-duty operation are priorities, despite the upfront infrastructure challenges and higher costs. As technology evolves and infrastructure expands, these differences may narrow, but for now, understanding the current landscape helps you make informed choices for sustainable bus fleets.

Frequently Asked Questions

How Do Initial Costs Compare Between Hydrogen and Battery Bus Fleets?

You’ll find that hydrogen bus fleets typically have higher initial costs compared to battery electric buses. Cost analysis shows that hydrogen vehicles require significant investments in infrastructure, like fueling stations, which increases upfront expenses. In contrast, battery electric buses usually have lower initial costs and benefit from existing electric infrastructure, making them more cost-effective initially. However, consider long-term operational costs when making your decision.

What Are the Safety Considerations for Hydrogen Versus Battery-Powered Buses?

You’re walking a tightrope when it comes to safety. Hydrogen buses pose a higher fire risk and chemical hazards due to its flammable nature, requiring strict handling and storage protocols. Battery-powered buses also have fire risks, mainly from thermal runaway. Both demand robust safety measures, but hydrogen’s risks are more immediate and explosive, so thorough training, proper maintenance, and emergency planning are essential to keep everyone safe.

How Scalable Are Hydrogen Refueling Stations Compared to Electric Charging Infrastructure?

Hydrogen refueling stations are less scalable than electric charging infrastructure due to lower refueling station density and limited grid integration. You’ll find electric chargers easier to deploy widely because they leverage existing electrical grids, allowing for rapid expansion. Hydrogen stations require specialized facilities and pose logistical challenges, making large-scale deployment slower. For your fleet, consider how quickly you can expand refueling options and how grid integration supports long-term growth.

What Is the Expected Lifespan of Hydrogen Versus Battery Bus Components?

You can expect hydrogen bus components to last around 10 to 15 years, thanks to their high durability, but they may face quicker wear due to the harsh operating environment. Battery bus components typically last 8 to 12 years, though technology obsolescence can shorten their effective lifespan as newer, more efficient batteries emerge. Regular maintenance helps extend component durability, regardless of the power source.

How Do Maintenance Requirements Differ for Hydrogen and Battery Electric Buses?

You’ll find that maintenance requirements differ markedly between hydrogen and battery electric buses. Hydrogen buses need regular checks of the hydrogen infrastructure and fuel system, which can be complex but generally involve fewer mechanical parts. Battery electric buses, on the other hand, require consistent battery maintenance, such as monitoring cell health and managing battery degradation. Overall, hydrogen buses may have lower ongoing maintenance, but both types demand specialized knowledge.

Conclusion

Ultimately, choosing between hydrogen and battery electric buses depends on your specific needs and future vision. Think of it as deciding whether to ride a Model T or a spaceship—both have their charm and challenges. As we look ahead, it’s clear that both technologies will shape the landscape of sustainable transit. So, whether you’re channeling your inner Edison or Ford, remember that the road to greener transportation is still being paved—so stay tuned for what’s next.